Pellet stoves are a fantastic heating solution, offering efficiency, eco-friendliness, and cost-effectiveness. But like any appliance, they aren’t immune to problems. One of the most frequent complaints from pellet stove users is related to pellet feeding issues. A malfunction in this system can disrupt heating, cause frustration, and potentially lead to costly repairs.

Understanding and addressing pellet feeding problems can extend your stove’s lifespan and improve its efficiency.

Whether you’re a first-time stove owner or a seasoned pro, this guide will walk you through common issues and practical solutions, ensuring your stove runs smoothly all winter long.

How Pellet Stoves Work

Pellet stoves rely on a mechanical system to feed fuel (compressed wood pellets) into the combustion chamber, where they burn to generate heat.

The process involves several key components:

- Hopper: A storage container for pellets.

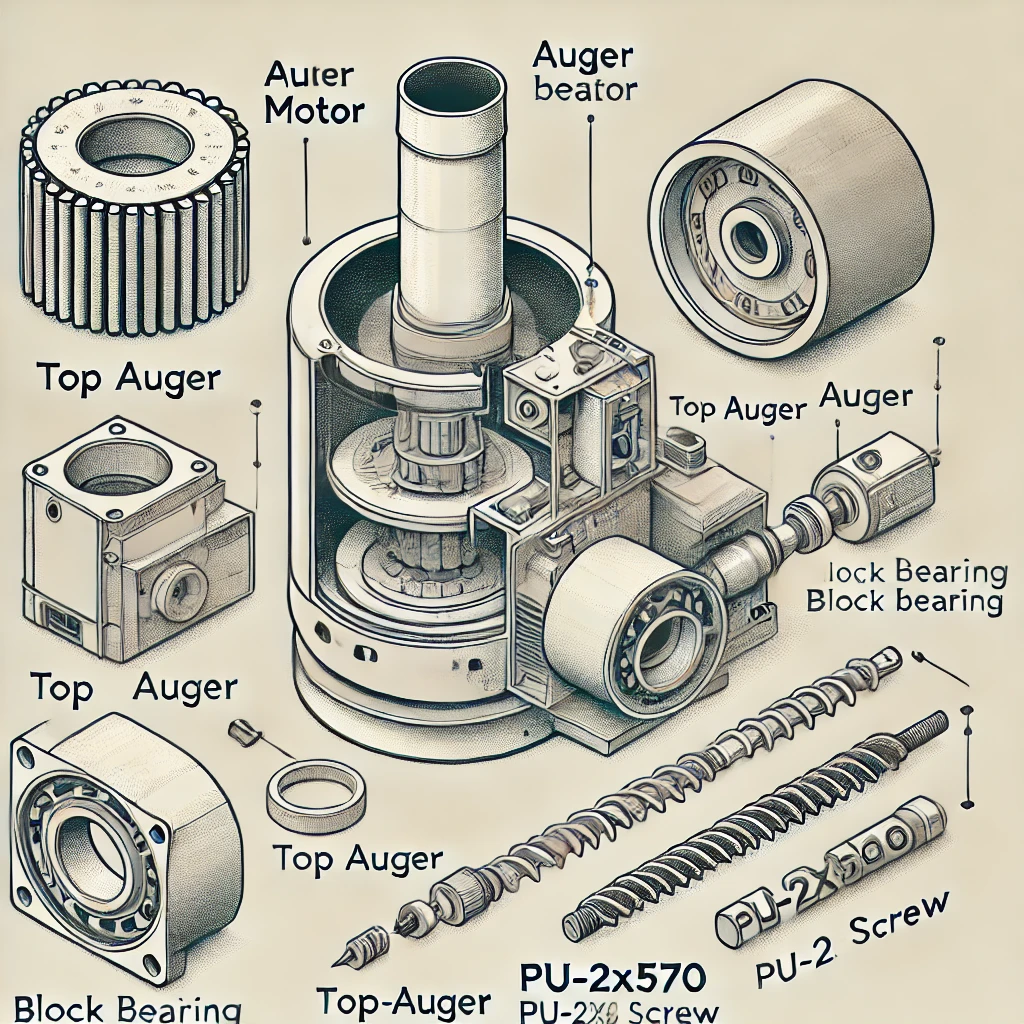

- Auger: A screw-like mechanism that moves pellets from the hopper to the burn pot.

- Combustion Chamber: The area where pellets burn to produce heat.

This intricate system ensures a steady supply of pellets for continuous heating. When one component fails, the entire process can be disrupted.

Common Symptoms of Pellet Feeding Problems

-

Irregular Feeding: Pellets feed too slowly, too quickly, or not at all, affecting heat output.

-

Loud Grinding Noises: The auger motor or pellets may be causing these unpleasant sounds.

-

Frequent Shutdowns: If the stove senses a problem, it may shut down as a safety precaution.

Recognizing these symptoms early can help you address the problem before it escalates.

Common Pellet Stove Pellet Feeding Issues and Fixes

Pellet stoves are efficient heating systems, but they can encounter various feeding issues that disrupt their operation. Below are some of the most common pellet feeding problems along with their fixes.

1. Feed Motor Issues

- Symptoms: The feed motor may slow down as the stove heats up or may not function at all.

- Fixes:

- Replace the feed motor if it is malfunctioning or if the bearings are worn out.

- For specific models like Quadrafire, ensure the capacitor is functioning properly; if it fails, it may need relocation away from heat sources or replacement.

2. Obstructions in the Feed System

- Symptoms: Pellets may not feed into the burn pot due to blockages.

- Fixes:

- Check for foreign objects in the hopper and feed chutes, such as plastic from pellet bags or excessive dust. Clean these areas thoroughly.

- Ensure that pellets are not bridging in the hopper; avoid using pellets longer than 1¼ inches.

3. Power Interruptions

- Symptoms: The stove may run fine at high settings but fail to maintain a fire at lower settings.

- Fixes:

- Clean dust and debris from the stove to ensure that the feed motor receives adequate power. Regular maintenance can prevent power interruptions.

4. Burnpot Issues

- Symptoms: Unburned pellets remain in the burnpot after shutdown.

- Fixes:

- This can occur if the feed was interrupted for too long or if there weren’t enough embers to ignite new fuel. Ensure that the stove is set correctly and that there is sufficient airflow to sustain combustion.

5. Draft and Airflow Problems

- Symptoms: Insufficient airflow can lead to poor burning performance.

- Fixes:

- Check for blockages in the venting system and ensure that draft settings are adjusted according to the manufacturer’s recommendations.

- If your stove has a damper rod, adjust it to optimize airflow for burning pellets efficiently.

6. Thermocouple Failures

- Symptoms: The stove may stop feeding pellets if it fails to detect heat.

- Fixes:

- Inspect and replace the thermocouple if necessary, as it plays a critical role in signaling when to feed pellets based on flame temperature. Ensure all connections are secure and clean.

7. Hopper and Lid Switch Issues

- Symptoms: The auger may not operate if hopper lids or doors are not properly closed.

- Fixes:

- Ensure that all lids and doors are securely closed, as many models have safety switches that prevent operation if these are ajar

Causes of Pellet Feeding Issues

Poor Pellet Quality

Pellet quality significantly impacts feeding efficiency. Damp, oversized, or crumbling pellets can jam the auger or fail to burn correctly, causing issues like:

- Inconsistent feeding.

- Excess ash buildup.

- Increased wear on components.

Always look for premium-grade pellets with low moisture content and uniform size to avoid these problems.

Blocked or Clogged Auger

Debris, ash, or pellet fragments can accumulate in the auger, creating blockages. Common causes include:

- Failure to clean the hopper and auger regularly.

- Using low-quality pellets that leave excessive residue.

Symptoms include grinding noises and pellets not reaching the combustion chamber.

Malfunctioning Auger Motor

The auger motor is the heart of the feeding system. If it’s worn out or defective, it may not have the strength to push pellets through, leading to:

- Slow or no feeding.

- Overheating of the motor due to strain.

- Frequent stove shutdowns.

Misaligned Auger or Components

Even slight misalignments in the auger or its housing can cause jamming or uneven feeding. This issue often arises due to improper installation or wear over time.

FAQs

Why is my pellet stove not feeding pellets consistently?

Inconsistent feeding is often caused by incorrect feed rate settings, poor-quality pellets, or a malfunctioning auger motor.

What type of pellets work best in a pellet stove?

Premium-grade pellets with low moisture content and uniform size are ideal for smooth operation.

How often should I clean the pellet feeding system?

Clean the system weekly to prevent ash and debris buildup that can obstruct pellet feeding.

Can I fix an auger jam myself?

Yes, most auger jams can be cleared by safely disassembling the hopper and removing the obstruction.

Is it safe to run a pellet stove with feeding issues?

No, operating a pellet stove with feeding problems can lead to safety hazards and damage to the stove.

Affiliate Disclosure: Fireplaceadviser.com is a participant in the Amazon Services LLC Associates Program. We may earn a commission when you click on certain links on this site and purchase.

Hello!! I am Jamal Khan. I often fix my home electric heaters and gas stove problems and research the common issues in the heating units to improve my knowledge and expertise. The aim of establishing fireplaceadviser.com is to share my expertise and knowledge with my audience.