The pellet stove auger is one of the most critical components of a pellet stove system. It plays a central role in feeding pellets from the hopper to the burn pot, ensuring consistent heat output. If your pellet stove auger not turning, you’re not alone.

Many pellet stove owners face this frustrating issue, especially during the colder months when a reliable heat source is essential.

The auger is a critical component that feeds pellets into the burn pot, so when it stops working, your stove can’t produce heat.

But don’t worry, most of the time, this issue can be resolved without needing a costly professional repair.

In this expert guide, we’ll walk you through the common reasons your pellet stove auger might not be turning and what you can do to fix it quickly and safely.

Why Did a Pellet Stove Auger Fail to Turn On?

The primary reasons a pellet stove might not turn on include a malfunctioning motor, pellet jams or clogs caused by damp or poor-quality pellets, and power supply issues such as a blown fuse or tripped breaker.

Additionally, faulty safety switches or sensors can prevent the auger from operating, especially if the stove overheats or a door is left open.

Mechanical issues like worn-out bearings or a misaligned auger screw can also hinder movement. Regular maintenance, proper alignment, and using high-quality pellets can help prevent these problems.

How to Fix a Pellet Stove Auger That Isn’t Working

- Identify the Problem:

- Check for a Jam: If the auger motor is running but no pellets are falling into the burn pot, the auger might be jammed. This could be due to a blockage in the auger housing or feed tube.

- Steps to Fix the Auger:

- Always unplug the stove before starting any maintenance to avoid accidents.

- Take out all the pellets from the hopper to get to the auger.

- Use a flashlight and a small mirror to check inside the auger housing for blockages. If you can reach the exterior auger housing, gently tap it with a rubber mallet to free any obstruction.

- Clean the Auger:

- If tapping doesn’t help, you might need to remove the auger:

- Unscrew the back or side cover of the stove.

- Remove the screws holding the auger motor in place.

- Slide the auger out of the feed tube.

- Clean the auger and feed tube thoroughly, removing any debris and vacuuming out any dust.

- If tapping doesn’t help, you might need to remove the auger:

- Check Sensors:

- Clean any sensors that might be obstructed, as they can affect the auger’s operation.

- Additional Troubleshooting:

- If the auger only spins briefly and then stops, there might be a problem with the motor or a more complex issue within the auger system. You might need to inspect the motor and electrical connections more closely.

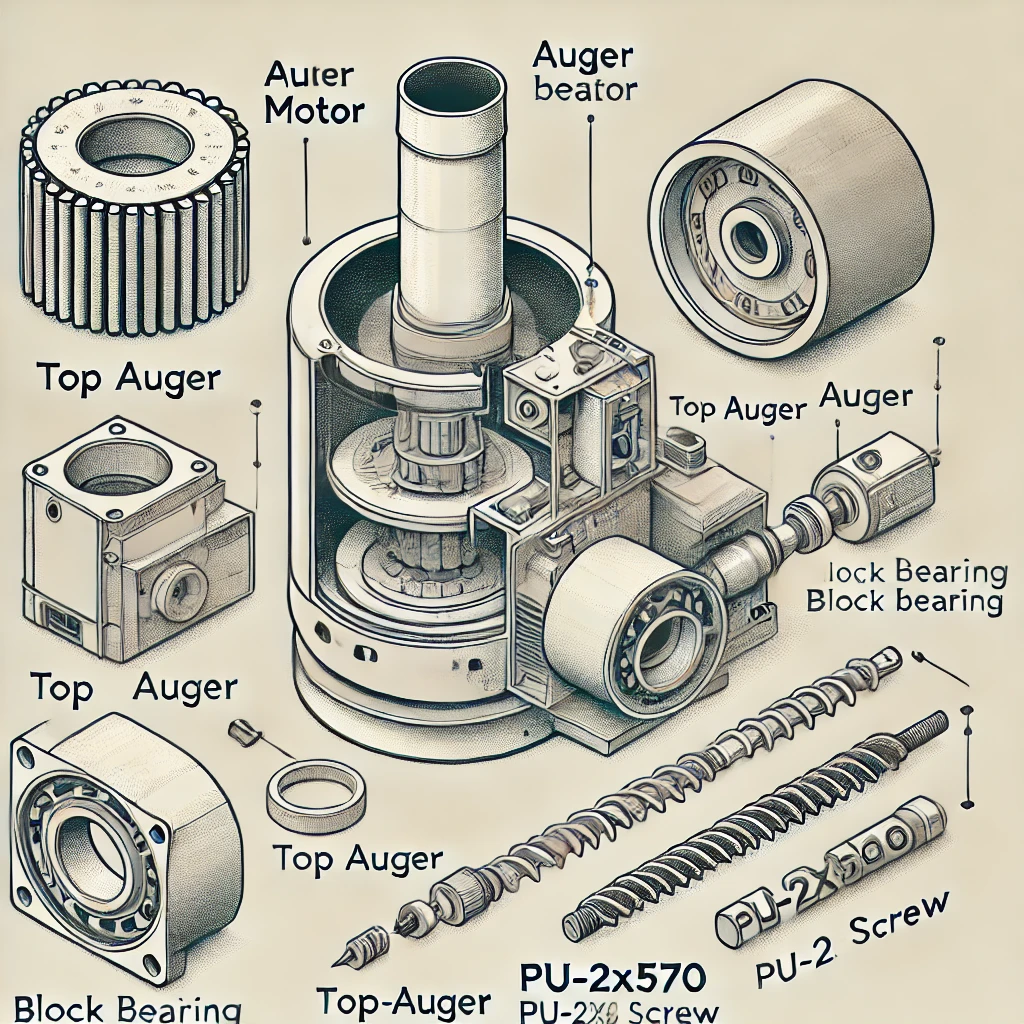

Anatomy of a Pellet Stove Auger

The pellet stove auger is one of the most critical components of a pellet stove system. It plays a central role in feeding pellets from the hopper to the burn pot, ensuring consistent heat output.

Here’s a detailed breakdown of the pellet stove auger and its components:

1. Auger Motor

The auger motor is the powerhouse behind the movement of the auger. It drives the rotation of the auger screw, pushing the pellets through the feed system.

The speed and timing of the motor determine the amount of pellets delivered to the burn pot, directly affecting the heat output.

- Function: Controls the movement of the auger to ensure the proper amount of fuel is delivered.

- Issues: If the motor fails or malfunctions, the auger will stop turning, and pellets won’t reach the burn pot.

2. Auger Screw

The auger screw is a long, spiraled metal shaft that moves the pellets from the hopper down into the burn pot. Its design ensures that the pellets are fed in a controlled and even manner.

- Function: Transports pellets from the hopper to the combustion chamber.

- Material: Typically made of durable stainless steel or other heat-resistant metals.

- Issues: Blockages, wear, or damage to the screw can cause jams, preventing pellets from moving.

3. Hopper

The hopper is where the pellets are stored before being fed into the auger. It holds a large amount of fuel, allowing the stove to run for extended periods without needing to be refilled.

- Function: Stores pellets and supplies them to the auger system.

- Issues: If pellets are damp or of poor quality, they can create clogs in the hopper and auger system.

4. Burn Pot

The burn pot is the area where the pellets are ignited and burned. The auger feeds the pellets into the burn pot at a controlled rate to maintain the desired temperature.

- Function: Receives pellets from the auger for combustion.

- Issues: If the auger doesn’t feed the correct amount of pellets, the stove may overheat, underperform, or fail to ignite properly.

5. Auger Bushing/Bearings

The auger’s movement is supported by bushings or bearings that reduce friction and allow smooth rotation. These are essential for maintaining the auger’s efficiency and preventing wear on the motor.

- Function: Provides support and smooth movement for the auger screw.

- Issues: If the bushings wear out, the auger may seize or struggle to turn, causing uneven pellet delivery.

6. Feed Tube

The feed tube is the conduit that guides the pellets from the hopper and auger system into the burn pot. It’s usually angled to ensure that the pellets flow smoothly.

- Function: Channels the pellets from the auger to the burn pot.

- Issues: Pellets can get stuck in the tube, leading to clogs or interruptions in fuel supply.

7. Safety Sensors and Switches

Many pellet stoves come with safety features that monitor the operation of the auger and motor. These switches can stop the auger if there’s an issue, such as overheating or blockages.

- Function: Ensures the auger operates safely and stops in case of malfunction.

- Issues: Faulty sensors may prevent the auger from turning, even when there’s no issue with the actual mechanism.

How a pellet Stove Work?

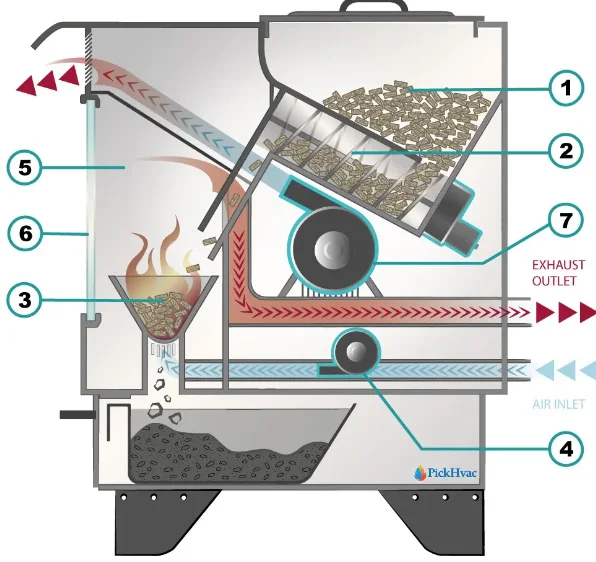

Pellet stoves are efficient heating appliances that burn compressed wood pellets to generate heat. Their operation involves several key components working together to ensure a clean and effective heating process.

Fuel Feeding System

The heating process of the stove begins with the hopper, which stores the wood pellets. An auger, a screw-like mechanism powered by an electric motor, transports the pellets from the hopper of the stove to the burn pot.

The auger turns to push the pellets horizontally into the burn pot, where they will be ignited.

Ignition

Once the pellets reach the burn pot of the stove, an automatic ignition system, also powered by electricity, ignites them.

This system ensures that the fire starts quickly and efficiently.

Combustion and Heat Exchange

As the pellets burn, the heat generated by the stove is transferred through a heat exchanger, which consists of metal tubes or plates that absorb heat from the flames.

A convection fan then circulates air over the heat exchanger, pushing the warmed air into the room, thereby heating the space effectively.

Exhaust Management

The combustion process produces gases that need to be expelled. An exhaust blower removes these gases from the burn pot and directs them outside through a vent pipe. This ensures that the indoor air quality remains clean and safe.

Temperature Control

Many pellet stoves come equipped with a thermostat that regulates the amount of pellets fed into the burn pot.

This allows for precise temperature control, as the stove can automatically adjust the feed rate to maintain the desired room temperature

Image Source: pickhvac.com

Common Issues with Pellet Stove Augers

-

Jams: Poor quality or oversized pellets can cause jams.

-

Motor Malfunctions: A burnt-out or faulty motor can stop the auger from turning.

-

Wear and Tear: Over time, the auger screw and motor can wear down, reducing efficiency.

-

Improper Pellet Feeding: If the auger is not properly calibrated, it may feed too many or too few pellets, affecting the stove’s performance.

Affiliate Disclosure: Fireplaceadviser.com is a participant in the Amazon Services LLC Associates Program. We may earn a commission when you click on certain links on this site and purchase.

Hello!! I am Jamal Khan. I often fix my home electric heaters and gas stove problems and research the common issues in the heating units to improve my knowledge and expertise. The aim of establishing fireplaceadviser.com is to share my expertise and knowledge with my audience.