When first encountering a wood stove, it’s easy to overlook the complexity hidden within the various parts of a wood stove. It’s only through regular use that one begins to appreciate how each part contributes to its overall functionality.

From the firebox, where the heat is generated, to the damper that regulates airflow, every component plays a crucial role in maintaining an efficient and safe burn.

In this post, I’m going to break down the anatomy of a wood stove, so you can get a better understanding of how your stove works and how to keep it in top shape.

- Flue Collar

- Blanking Plate

- Extension tube

- Firebricks or Liners

- Primary air controls

- Main Fire Door

- Baffle or throat plate

- Secondary Air Controls

- Wood burner

What are the Common Parts in a Wood Stove?

1. Flue Collar

The flue collar of a wood stove connects the stove to the chimney or flue pipe. It’s essentially the exit point for smoke and gases, guiding them safely out of your home.

The flue collar is crucial for ensuring proper ventilation and efficient burning, as it helps maintain the right draft within the stove.

A well-functioning flue collar is key to avoiding smoke leakage and keeping the fire burning cleanly.

2. Blanking Plate

A blanking plate is a metal cover used to seal off unused openings on a wood stove. These openings might be intended for additional components or future upgrades.

By using a blanking plate, you can maintain the efficiency of the stove by preventing air leaks and ensuring that the heat stays where it’s needed.

It’s a simple yet important component that contributes to the overall safety and efficiency of your stove.

3. Extension Tube

The extension tube is an additional pipe that can be attached to the flue pipe to extend its length. This is often used when the flue needs to reach a higher point to ensure proper ventilation.

The extension tube helps in maintaining the right draft, ensuring that smoke and gases are effectively drawn out of the stove and up the chimney. It’s especially useful in installations where the standard flue pipe length isn’t sufficient.

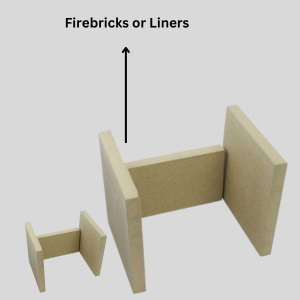

4. Firebricks or Liners

Firebricks or liners are the heat-resistant bricks or panels that line the interior of a wood stove. Their primary role is to protect the stove’s metal body from the intense heat generated by the fire.

Firebricks help to reflect heat back into the firebox, improving the stove’s efficiency by allowing it to burn hotter and cleaner. They also play a vital role in extending the life of your stove by preventing heat damage to the stove’s structure.

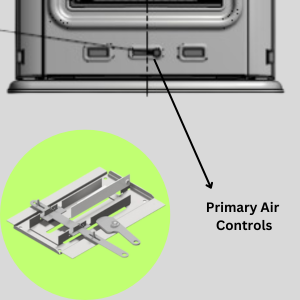

5. Primary Air Controls

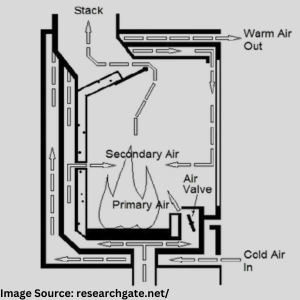

Primary air controls are the adjustable mechanisms on a wood stove that regulate the amount of air entering the firebox. This airflow is essential for starting and maintaining a fire.

By adjusting the primary air controls, you can control the fire’s intensity and burn rate.

Opening the controls allows more air in, feeding the fire and increasing heat output, while closing them slows the burn for a longer, more sustained fire.

6. Secondary Air Controls

Secondary air controls are additional air inlets on a wood stove that provide air to the top of the firebox. This air helps to ignite and burn the gases released by the wood as it heats up, contributing to a more efficient and cleaner burn.

By adjusting the secondary air controls, you can fine-tune the stove’s performance, achieving the right balance between heat output and fuel efficiency.

7. Main Fire Door

The main fire door is the door through which you load wood into the stove. It’s designed to be airtight when closed, ensuring that the fire burns efficiently and safely.

The main fire door often has a glass window, allowing you to view the fire while it burns.

This door is crucial for both functionality and safety, as it prevents smoke from entering the room and maintains proper airflow within the stove.

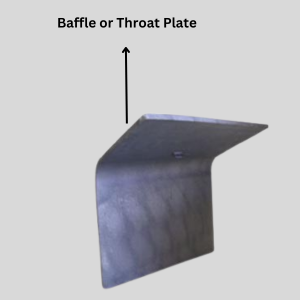

8. Baffle or Throat Plate

A baffle or throat plate is a metal plate located inside the wood stove, above the firebox. Its purpose is to deflect the rising hot gases and smoke, making them circulate around the firebox before exiting through the flue.

This circulation improves the stove’s efficiency by allowing more heat to be absorbed by the stove before the gases escape.

The baffle also helps to reduce the amount of creosote buildup in the chimney by promoting more complete combustion of the wood.

9. Wood Burner

The wood burner also known as firebox is the central component of a wood stove, where the wood is burned to produce heat. It’s designed to contain and manage the fire, ensuring that it burns safely and efficiently.

The wood burner is lined with firebricks or liners to withstand high temperatures and is equipped with air controls to regulate the burn rate.

The design of the wood burner plays a critical role in how well the stove heats your home and how much fuel it consumes.

Parts in a Modern Technology Wood Stove

Many of the fundamental principles remain unchanged from the previous discussion, so there’s no need to revisit them. However, modern wood stove manufacturers have added additional systems and components to enhance functionality.

- Tertiary Air System: Some modern stoves have a tertiary air system that introduces even more air for combustion, often through dedicated channels, for cleaner burns.

- Catalytic Combustor: A device used in some modern stoves that burns off excess smoke and gases before they leave the flue, further reducing emissions and increasing efficiency.

- Glass Door: The door of the stove, often made of heat-resistant glass, allowing users to view the fire while keeping the heat in and the smoke out.

- Ash Pan: A removable tray or compartment where ashes collect for easy cleaning.

- Heat Exchanger: Some stoves have a heat exchanger to improve efficiency by transferring more heat from the stove into the room.

- External Air Supply: An optional feature in airtight stoves that draws air from outside the home directly into the stove, improving efficiency and air quality in tightly sealed modern homes.

- Blower/Fan (optional): An electric fan used to circulate warm air from the stove into the room, enhancing heat distribution.

- Door Seals and Gaskets: These components ensure that the stove is airtight when the door is closed, crucial for controlling the burn rate and maintaining efficiency.

- Thermometer or Temperature Gauge: Used to monitor the stove’s internal temperature, helping the user maintain optimal burning conditions.

Affiliate Disclosure: Fireplaceadviser.com is a participant in the Amazon Services LLC Associates Program. We may earn a commission when you click on certain links on this site and purchase.

Hello!! I am Jamal Khan. I often fix my home electric heaters and gas stove problems and research the common issues in the heating units to improve my knowledge and expertise. The aim of establishing fireplaceadviser.com is to share my expertise and knowledge with my audience.