In the world of firewood processing, efficiency and durability are paramount. Whether you’re a seasoned professional or a weekend warrior, having the right equipment can make all the difference in maximizing productivity and minimizing downtime.

As we venture into 2025, the demand for robust firewood processors continues to rise, prompting manufacturers to push the boundaries of innovation.

In this guide, we’ll explore the top three heavy-duty firewood processors of 2025, meticulously engineered to tackle even the toughest timber with unparalleled efficiency and reliability.

Our Top Picks:

Premium Pick

YIHUITONG 45 Ton Firewood Processor with Trailer Hitch safety.

Best Value

YIHUITONG 30 Ton Remote Control Skidsteer Firewood Processor.

Expert Tips for Choosing a Firewood Processor

- Determine the volume of firewood you plan to process regularly. This will help you choose a processor with the suitable capacity and capabilities to meet your demands.

- Firewood processors can be powered by various sources such as electricity, gasoline, diesel, or hydraulics. Consider availability, cost, and convenience when selecting the best power source that suits your operation.

- Invest in a processor with quality materials and robust construction to ensure longevity and reliability, especially if you anticipate heavy usage.

- Look for features that enhance efficiency, such as fast cycle times, easy adjustments for different log sizes, and ergonomic design to minimize operator fatigue.

- Safety should be a top priority. Choose a processor with safety features like guards, emergency stops, and automatic log clamps to protect operators from potential hazards.

- Opt for a firewood processor that is easy to maintain and service. Accessible components, clear maintenance instructions, and availability of spare parts can make upkeep more manageable.

- Research customer reviews, seek recommendations from other firewood processors, and consult industry experts to gather insights on different models and brands.

- Arrange a demonstration or test run of the firewood processor before purchasing. This lets you assess its performance firsthand and ensure it meets your requirements.

- Factors such as fuel, maintenance, and potential repairs are essential when evaluating the overall value of the processor, not only the initial purchase price but also long-term costs.

- If you have diverse processing needs, consider a versatile processor, such as the ability to handle different log sizes and types or optional attachments for additional functionality.

Top 3 Most Productive and Heavy Duty Firewood Processors

- Yihuttong 45 Ton firewood processor with trailer hitch safety.

- Yihuttong 30 Ton Remote Control Skidsteer Firewood Processor.

- Forestry Machinery 30ton Skid Steer Firewood Processor.

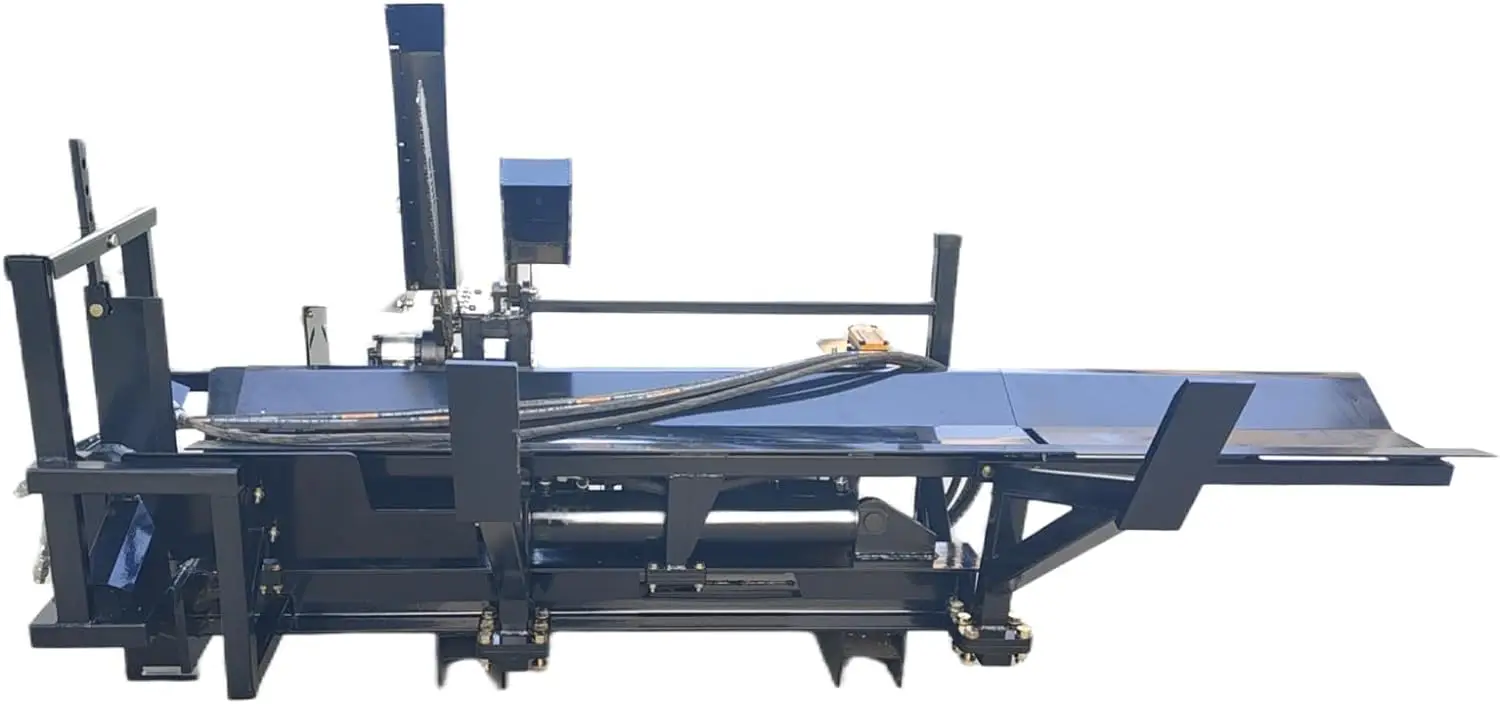

1. YIHUITONG 45 ton Firewood Processor with Trailer Hitch safety.

Introducing the YIHUITONG 45 ton Firewood Processor with Trailer Hitch, a robust and versatile solution for all your firewood processing needs. Powered by a formidable 20HP HONDA GX630 gasoline engine, this processor delivers ample power for cutting and splitting logs with ease.

Its high-performance air filter system and large-capacity oil tank ensure smooth operation and long-lasting durability, even under demanding conditions. Equipped with a 25″ STIHL bar and chain crafted from high-quality steel, it effortlessly handles a wide range of wood types and sizes, making light work of even the toughest cutting tasks.

Plus, with its 3M conveyor belt, logs are continuously fed into the cutting chamber for efficient and uninterrupted processing.

Featuring hydraulic manual operation and a multifunctional control panel, adjusting cutting speed, depth, and feeding speed is a breeze. Safety is paramount, with an emergency stop button system to prevent accidents and machine damage.

The YIHUITONG processor’s user-friendly design ensures ease of use and maintenance, catering to both seasoned professionals and beginners alike. With a 45T splitting capacity and the ability to split logs into 4 or 6 equal pieces, it’s perfect for both residential and commercial use.

From splitting firewood for heating and cooking to outdoor gatherings like camping and backyard barbecues, this versatile tool excels in various applications.

Key Features:

- Powerful 20HP HONDA GX630 gasoline engine.

- 25″ STIHL bar and chain for versatile cutting.

- 3M conveyor belt for continuous feeding.

- Hydraulic manual operation with multifunctional control panel.

- User-friendly design for easy operation and maintenance.

- 45T splitting capacity with 4 or 6-way splitting wedge.

- Safety features including emergency stop button and safety net.

| Pros | Cons |

|---|---|

| Powerful engine | May be heavy and bulky to move |

| Versatile applications | May require periodic maintenance |

| User-friendly design | |

| Safety features |

What I Like:

I appreciate the robust power of the engine, effortlessly tackling even the toughest cutting tasks. The versatility of applications is also a huge plus, allowing me to use it for various needs, from heating to outdoor gatherings.

The safety features offer peace of mind, especially during intense operation.

What I Don’t Like:

While the power is commendable, the machine’s weight and bulkiness can pose a challenge, especially when moving it around. Additionally, the reliance on gasoline means ongoing fuel costs, and the initial investment might be steep for some.

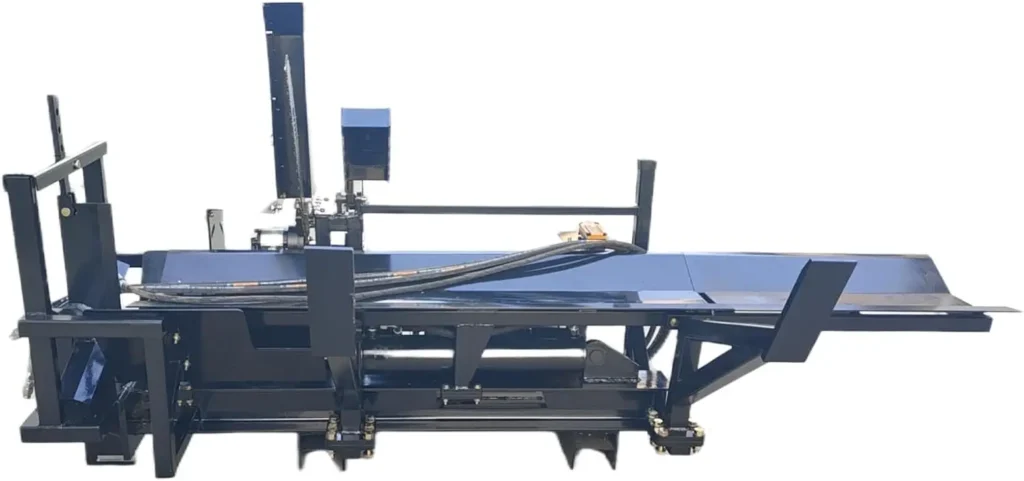

2. YIHUITONG 30 Ton Remote Control Skidsteer Firewood Processor.

Introducing the YIHUITONG 30 Ton Remote Control Skidsteer Firewood Processor, a robust and efficient solution for processing firewood with ease. This equipment seamlessly integrates with Skid Steers and tractors through its installation plate, ensuring a secure connection for optimal performance.

Driven by the Skid Steer, the processor efficiently shovels round wood onto the wood conveyor via the loading shovel. Once in place, the teeth securely fasten the wood, allowing the saw to swiftly cut through it.

As the wood is severed, it descends onto the wood receiving plate of the main machine. Utilizing the wood splitting cylinder, the processor effortlessly splits the wood into four, six, or eight pieces, enhancing efficiency and productivity.

Key Features:

- Seamless integration with Skid Steers and tractors.

- Efficient wood processing with a 30-ton capacity.

- Remote control operation for enhanced convenience.

- Versatile wood splitting options: four, six, or eight pieces.

- Sturdy construction for durability and longevity.

| Pros | Cons |

|---|---|

| Efficient wood processing | Requires Skid Steer or tractor for operation |

| Remote control operation | Initial setup may require assistance |

| Versatile wood splitting options | Limited to specific wood sizes |

What I Like:

I appreciate the seamless integration of the YIHUITONG 30 Ton Remote Control Skidsteer Firewood Processor with Skid Steers and tractors, making it easy to use with existing equipment.

The remote-control operation adds a layer of convenience, allowing me to control the processor from a distance, which enhances safety and efficiency during operation.

What I Don’t Like:

While the processor offers efficient wood processing, the initial setup may require some assistance, especially for those not familiar with installation procedures.

Additionally, the requirement of a Skid Steer or tractor for operation might be limiting for users who don’t already have access to this equipment.

3. Forestry Machinery Skid Steer Firewood Processor.

The Forestry Machinery Skid Steer Firewood Processor is a versatile and powerful tool designed for efficiency and convenience in wood processing tasks.

This model seamlessly integrates with skid steers or tractors equipped with a front bucket, as well as forklifts or tractors with arms, offering flexibility in operation.

With a robust 30-ton splitting force, it effortlessly handles logs up to 450mm in diameter and 580mm in length, while providing a maximum feeding length of 6 meters.

Packing conveniently in a 3 CBM shipping package, this processor eliminates the need for a separate engine as it attaches directly to compatible machinery.

Key Features:

- Compatible with skid steers or tractors with front buckets

- 30-ton splitting force for efficient wood processing

- Max cutting diameter of 450mm and cutting length of 580mm

- 6-meter feeding length for handling large logs

- No separate engine required, attaches to existing machinery

| Pros | Cons |

|---|---|

| Remote-controlled operation for enhanced safety and convenience. | May require assembly of tubes and lifter arm upon delivery. |

| Manual or hydraulic adjustable wedge for versatile splitting options. | Remote operation may take some time to get used to. |

| High work efficiency, allowing one person to complete all operations. | |

| Hydraulic control system and automatic procedures improve work efficiency. |

What I Like:

I appreciate the convenience and efficiency of the remote-controlled operation, which not only enhances safety but also allows me to handle all tasks single-handedly.

The high work efficiency and versatile splitting options provided by the manual or hydraulic adjustable wedge are also noteworthy features that make wood processing tasks much easier.

What I Don’t Like:

While the remote operation is convenient, it took me some time to get used to it initially. Additionally, the assembly required upon delivery can be a bit cumbersome, although it’s manageable with some patience.

Related Posts:

Importance of Firewood Processor

- Automates cutting, splitting, and stacking, reducing manual labor.

- Processes large volumes of firewood quickly.

- Ensures uniform sizing and quality for customer satisfaction.

- Reduces risks associated with manual handling of tools.

- Long-term savings outweigh initial investment.

- Adjustable settings to meet varying customer demands.

- Ensures steady supply during peak demand periods.

- Contributes to sustainability by utilizing wood from renewable sources.

Firewood Processor Maintenance Guide

- Remove debris and sawdust buildup.

- Check moving parts for signs of damage.

- Keep all moving parts well-lubricated.

- Check fluid levels and inspect for leaks.

- Sharpen or replace cutting blades of the firewood processor as needed.

- Inspect wiring and components for damage.

- Ensure all safety features are functioning properly.

- Check and adjust tension settings and alignments.

- Store in a clean, dry, and secure location.

- Refer to the manufacturer’s maintenance instructions.

Affiliate Disclosure: Fireplaceadviser.com is a participant in the Amazon Services LLC Associates Program. We may earn a commission when you click on certain links on this site and purchase.

Hello!! I am Jamal Khan. I often fix my home electric heaters and gas stove problems and research the common issues in the heating units to improve my knowledge and expertise. The aim of establishing fireplaceadviser.com is to share my expertise and knowledge with my audience.